Companyoverview

"We deliver what we promised"

Proudly powered with decades of professional experience in the market, we stand here to introduce our company. We are a closed-book family business company registered under the name Alalamiya for Plastics Technology (Sharky) S.A.E., ISO9001/2015 - ISO14001/2015 - ISO45001/2018 certified for plastic products and molds.

The early beginning of the company was in 1983 as a sole proprietorship.

Through four decades of actively serving the Egyptian market our company had acquired experience, trust, and good reputation.

The legal entity of the company had changed through the years to cope with the market dynamic nature taking into consideration the company strategy and vision.

The company management is performing sustainable improvement proccesses to leverage the overall business outcomes and environment.

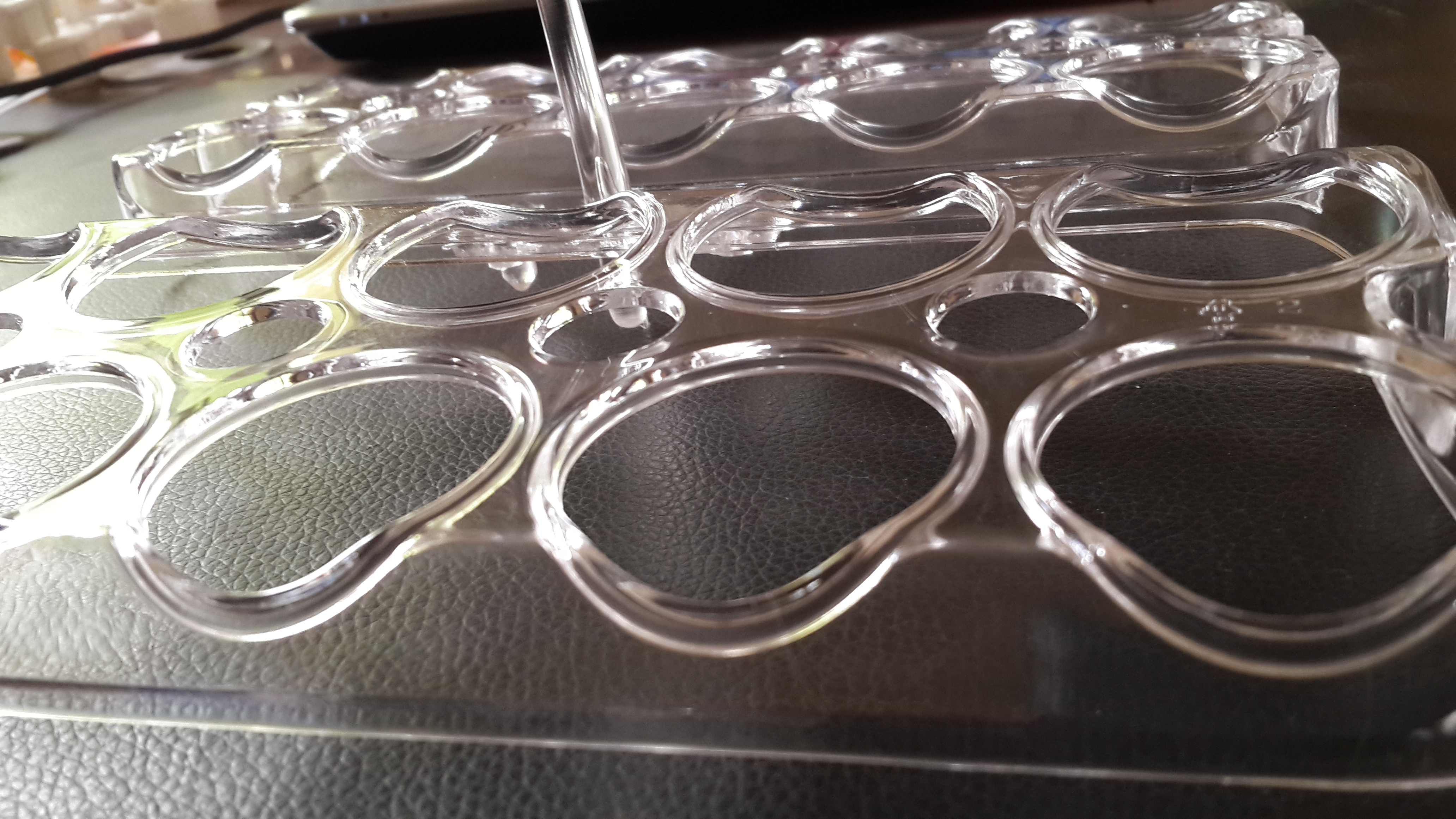

- High quality injection molding plastic products that serves different industries as textile, cosmetics, detergents, home appliance, medical devices, and more.

- High quality extrusion blow molding plastic containers that serves different industries as detergents, chemicals, cosmoceuticals, home appliance, and more.

- Injection molds, blowing molds, and spare parts

Our strategy depends on offerring the market a portfolio of distinctive quality products that adds up value to our customers, industry and society.

Our mission statement

Sustainability

The dynamic nature of the market inspired and forced us to find our own path to have sustainable continuous improvement and performance enhancement processes.

We developed a learning environment internally to encourage our team to sharpen their skills and capabilities.

We also consider the social responsibility part to be a key impact for adding value to the industry and the society as well. We offer knowledge and support to engineering students graduation projects, start-ups in the field, and new comers to business.

We try with consistent steps to find new ways to add more value to our employees, our markets, society, and the environment.

Business upgrade

We started to offer more professional services to our customers as:

- Products technical modification or redesign

- Offering a 3d printed prototypes for market studies

- Improving production quality and productivity for other customers

- Offering turnkey production lines

- Work as a third party (consultant) for design, quality check and inspection for molds manufactured abroad for our customers.

- Offering mold maintenance services for complicated and high quality molds to local customers.

The new business promotion upgraded the type and quality of our customers. And the scope of customers had been widened since then.

We proudly started to offer our services to

- Medical syringe manufacturing companies

- Medical instruments manufacturing companies

- Medical Supplies manufacturing companies

- Home appliance manufacturing companies

- Airplane engineering parts (inside the cabin)

- Office Furniture manufacturing companies

- Floor cleaning machines

Factory layout and machinery:

The main production facility is located in Obour industrial city. As a key advantage strategy, we follow up an update routine for our machines quality and performance. We regularly replace old machines with more advanced and productive machines and accessories to offer our customers with up-to-date competitive niche advantage over their competitors.

- Latest control systems

- Extra outputs for advanced molds

- High production speed

- Online workflow process